electrical center b2c

65mm 85mm 130mm Wheel Hub Motor Kit Encode DC 6V 12V 24V Speed 12- 1360rpm Metal Gearbox Encoder Moter RC Car Robot JGA25-370

Couldn't load pickup availability

SPECIFICATIONS

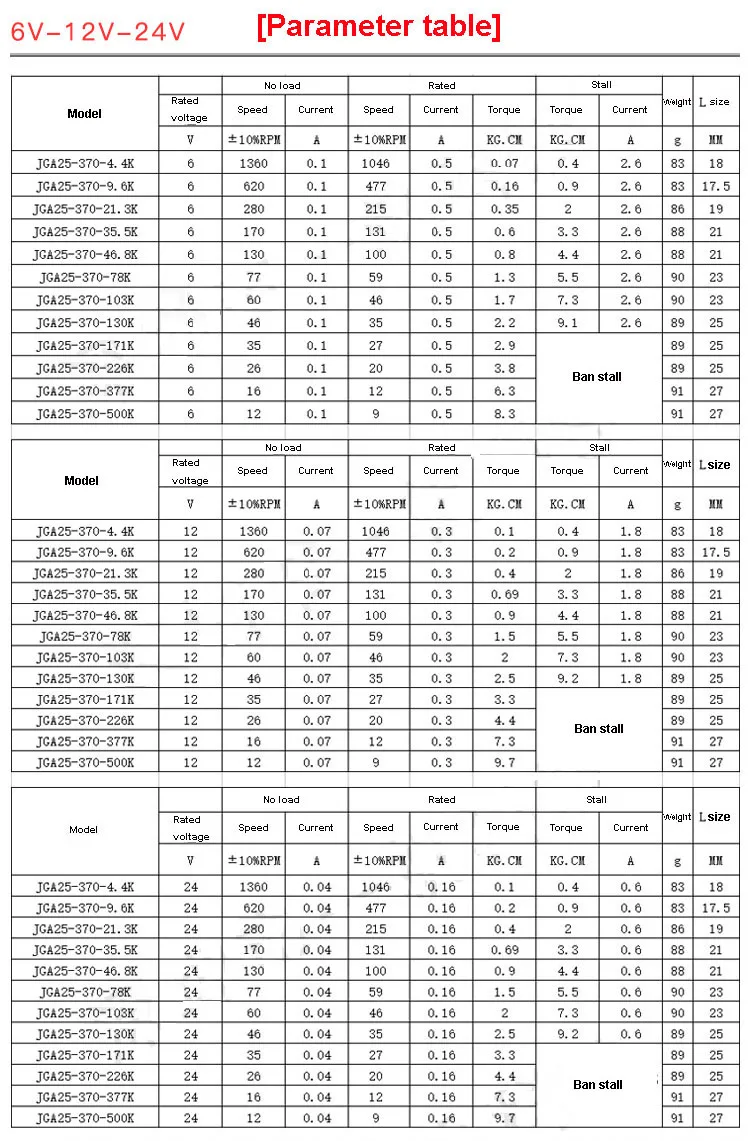

65mm 85mm 130mm Wheel Hub Motor Kit Encode DC 6V 12V 24V Speed 12- 1360rpm Metal Gearbox Encoder Moter RC Car Robot JGA25-370

electric hub motor for car,hub motors,wheel motor

Brand Name: HYSMOTOR

Certification: CCC

Certification: ROHS

Origin: Mainland China

Continuous Current(A): 100ma

Output Power: 3W

Commutation: Brush

Type: Gear Motor

Protect Feature: Totally Enclosed

Construction: Permanent Magnet

Usage: BoAt

Usage: car

Usage: Electric Bicycle

Usage: Fan

Usage: Home Appliance

Efficiency: IE 1

Model Number: JGA25-370 Encoder Motors

Torque: max 8kg.cm

The following is the picture of the motor

Wiring method:

-

Red Wire - positive power supply of motor(+)(change positive and negative of motor the rotation will change)

-

White Wire - negative power supply of motor(-)(change positive and negative of motor the rotation will change))

-

Yellow Wire - signal feedback (motor one turn has 11 signals)

-

Green Wire - signal feedback (motor one turn has 11 signals)

-

Blue Wire - positive of encoder power supply(+)(3.3-5V),cannot be wrong

-

Black Wire - negative of encoder power supply(-)(3.3-5V),cannot be wrong

Care Instructions

Care Instructions